Special lifting cushion solutions

Buitink Technology designs, develops and produces custom made lifting cushion systems. Usually it concerns a challenging industrial issue for which no standard solution is available.

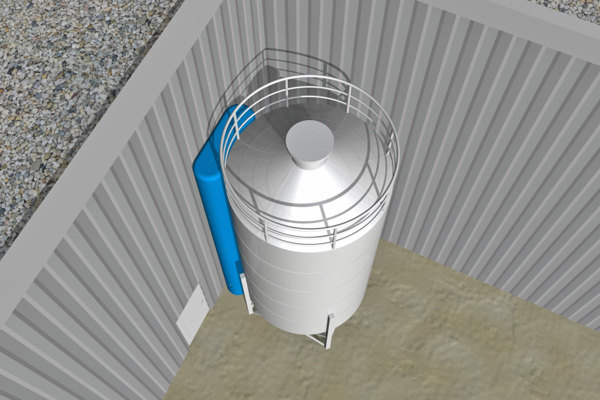

Side support silo

This project deals with a fully loaded silo where the support beams were broken. The silo tended to collapse and fall against a building wall. Buitink engineers developed an inflatable lifting cushion system. The cushion was placed between the silo and the building wall, such that the silo could be emptied without any risk.

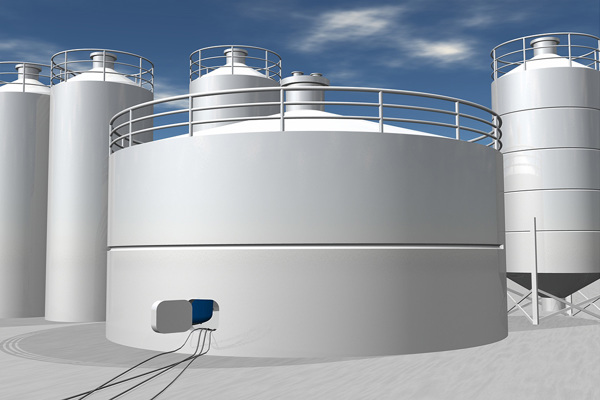

Support collapsed roof

This project deals with a floating covering of a chemicals silo that was collapsed. The location was an explosion risk area. In order to safely work inside the silo, Buitink provided a temporary inflatable support construction through the man-hole.

For this project Buitink Technology developed and produced 4 lifting cushions to provide protection for the workers. Due to explosion risk the cushions were inflated with nitrogen. A poly-ethylene cover protected the cushions for benzene vapors.

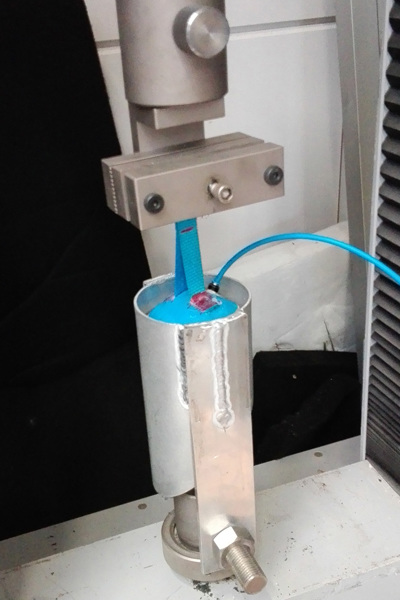

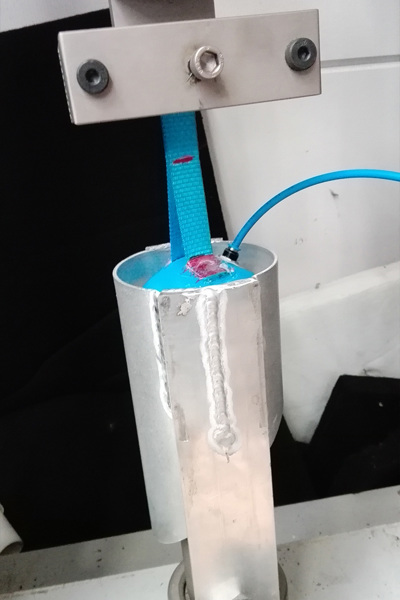

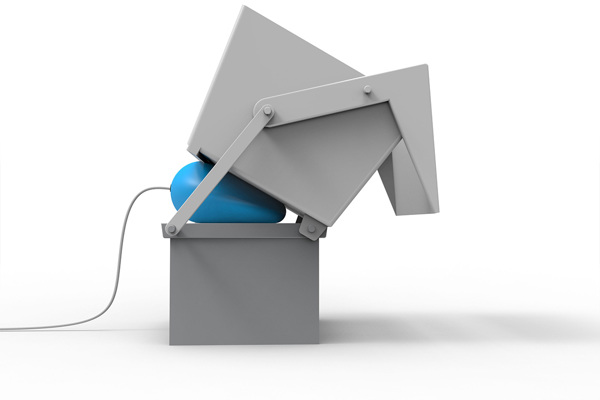

Inflatable lift mechanism

This lifting mechanism operates based on the friction between contact surface of the bellow and the object to be lifted. This mechanism allows to lift e.g. hollow tubes. The lifting power is by default equally distributed along the surface area, preventing damage of the object. It allows also lifting objects without having lifting connections.

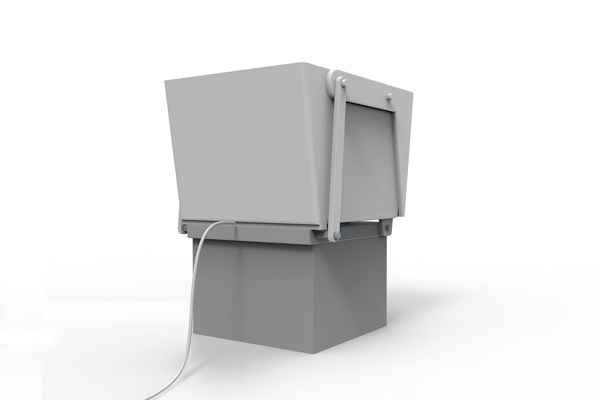

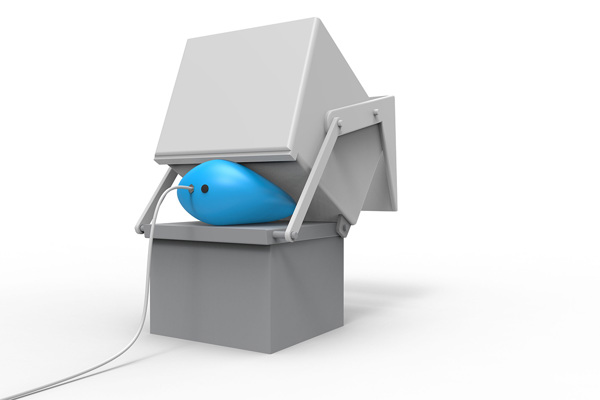

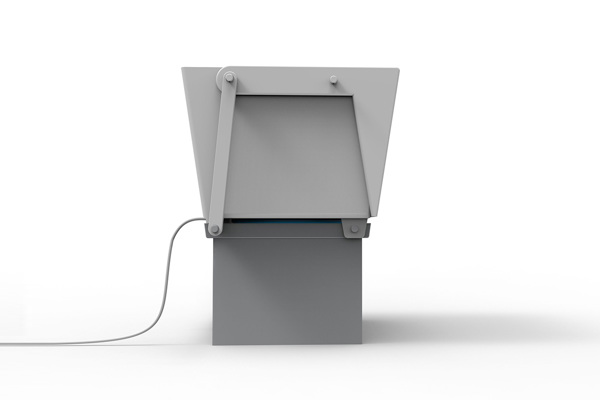

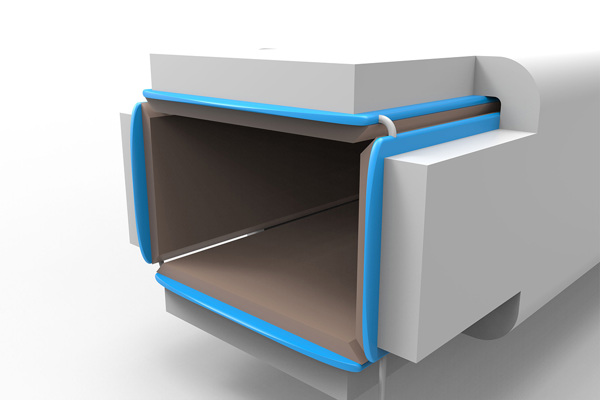

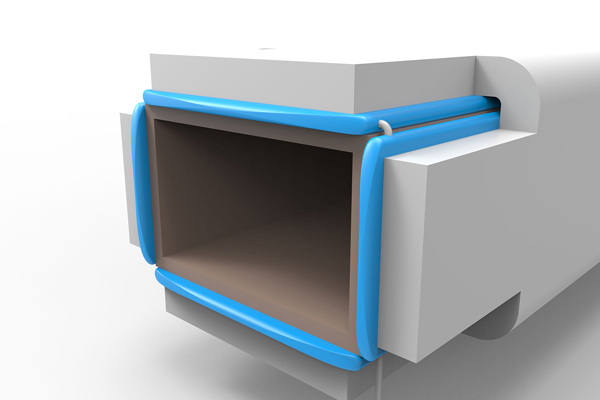

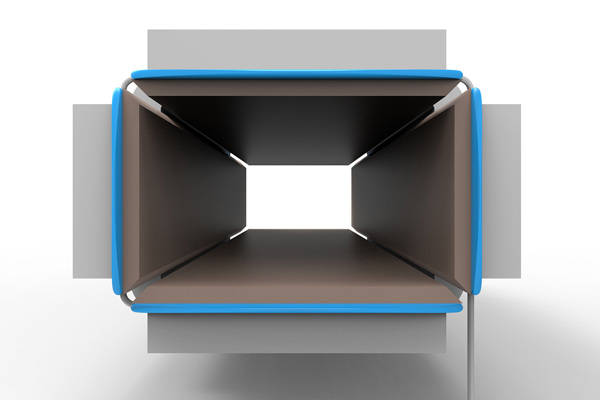

Lifting bags for tilting

Lifting bags can be applied in tilting systems. We produce custom made lifting bags in various shapes and sizes. The optimal shape and size is determined in cooperation with the client.

Below visuals show a nice example of a tilting system where a container is turned over trough inflating a lifting cushion.

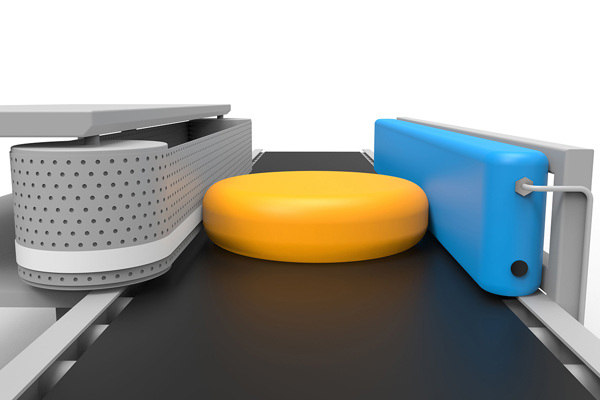

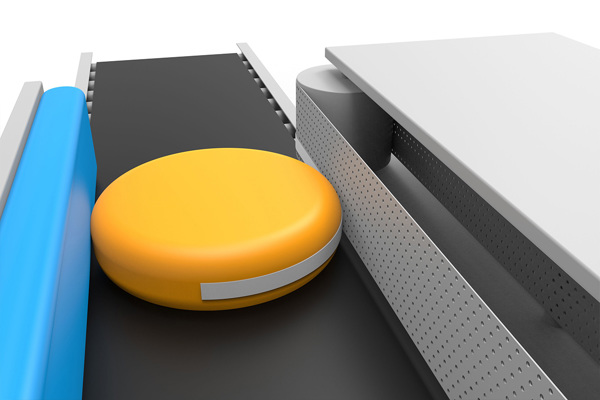

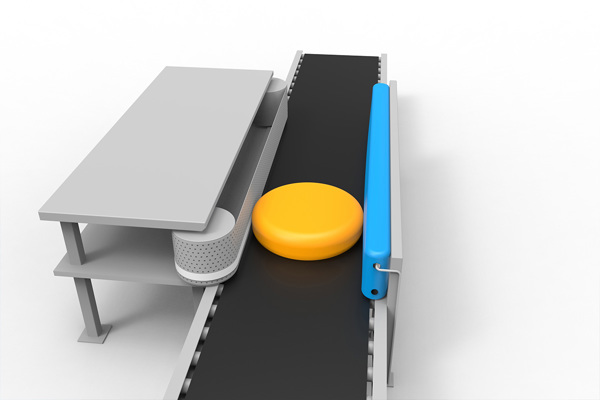

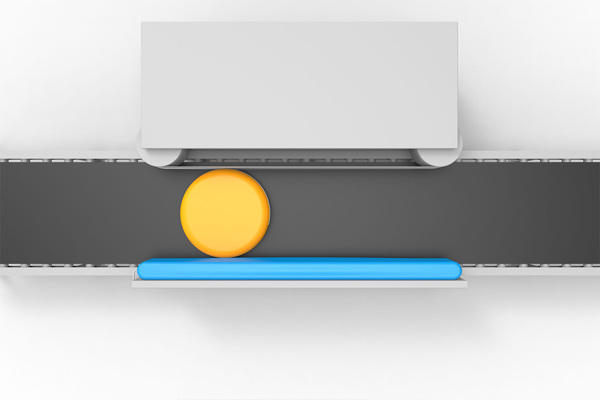

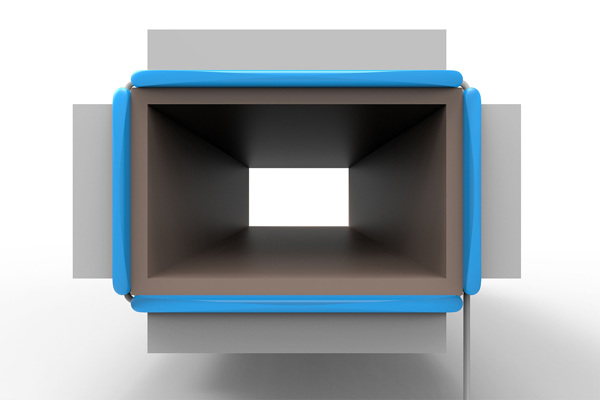

Product press for applying labels

Our inflatable cushions can be applied for guidance and evenly distributed pressing; e.g. in the process of labeling cheese. Using cushions eliminates the risk of damaging relative soft products.

Below visuals show a nice example of this system where cheese on a conveyor belt is pressed against the labeling machine using our pneumatic cushion.

Press adhesive connections

Pneumatic lifting bags are well applicable for pressing glued connections without damaging the product. We produce various models in different sizes of lifting bags.

Below visuals show a nice example of this system in which 4 different parts are glued and pressed through inflating pneumatic cushions.

Pneumatic bags for fill process

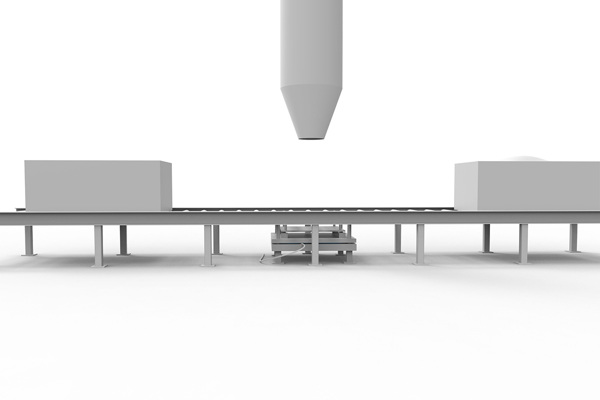

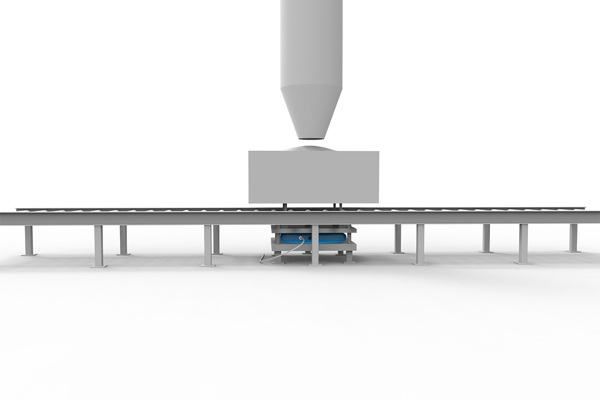

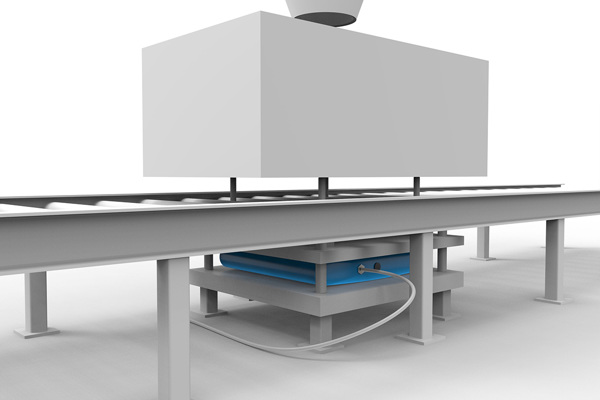

Lifting cushions can be applied in processes where solid bulk materials from a silo have to be weighed in containers or big bags through a bagging machine.

An empty container on a belt conveyor underneath a silo can be lifted from the belt conveyor by means of an inflatable lifting cushion. When the container is full, the cushion is deflated to put back the container on the conveyor belt for further transport.

Pneumatic bags for conveyor belts

An interesting application of inflatable lifting bags is for the crossover of belt conveyor and chain conveyor.

The conveyor belt section in between chain conveyors can be moved up- or downwards through lifting bags. In this way the transport direction is controlled, either through the belt conveyor or the chain conveyor.

Questions?

Do you have questions or want more information? Please feel free to contact us. Call us at +31 (0)316-250830. But even easier: fill out the contact form below directly. We will contact you as soon as possible!

Contact form

Contact form +31 (0)316-250830

+31 (0)316-250830