- Buitink Technology >

- Industry >

- Bellows >

- Techniques

Techniques to make expansion joints

Several techniques or combination of techniques enable the production of fabric expansion joints. Which way of production is chosen depends on:

- The application of the expansion joint

- e.g. is 100 % air- or liquid tight required? - What material of construction is required.

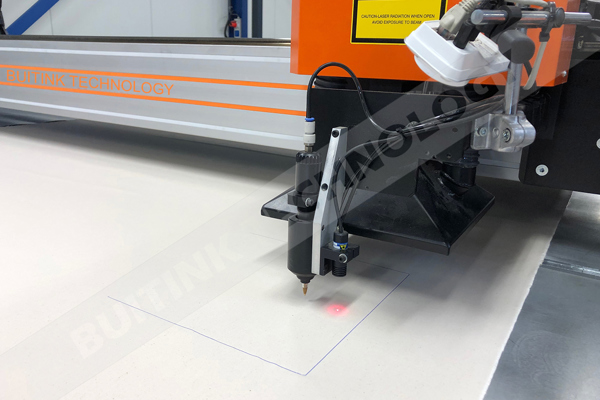

Laser en cutting techniques

- Automated unwinding and cutting of fabric (with pizza or rotating knife);

- Automated cutting of fabric using a laser cutter (cutting table 3 x 15 meter).

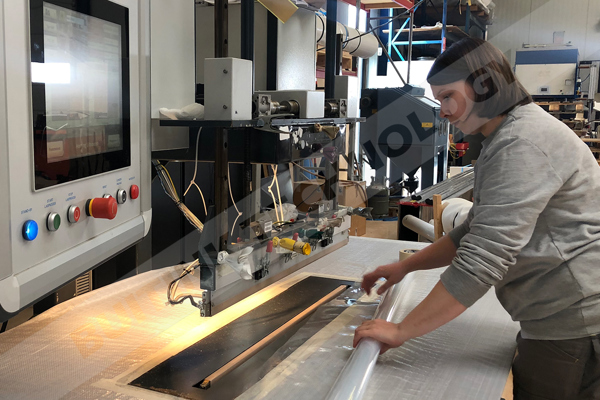

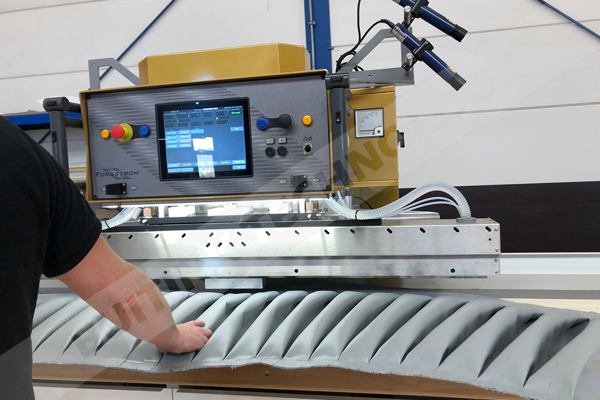

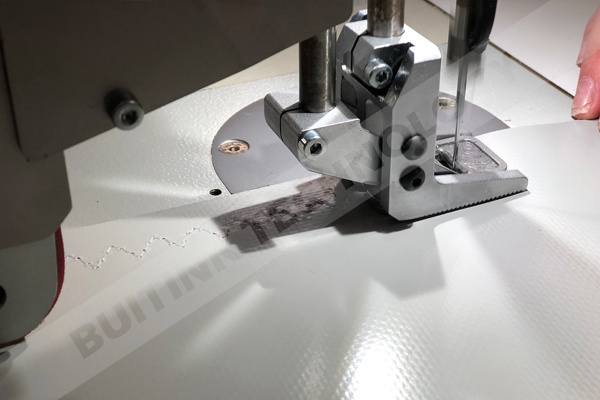

Sealing techniques

Buitink Technology uses all kinds of possible techniques to seal and combine canvas, foils and fabric to make sleeves and fabric expansion joints.

Think about:

- Stitching and sawing;

- High frequent welding(HF welding);

- Ultrasonic welding;

- Hot air welding;

- Seamtec welding;

- Miller welding;

- Gluing;

- Clamping.

Below you find pictures of several bonding techniques we use in our production facilities.

Questions?

Do you have questions or want more information? Please feel free to contact us. Call us at +31 (0)316-250830. But even easier: fill out the contact form below directly. We will contact you as soon as possible!

Contact form

Contact form +31 (0)316-250830

+31 (0)316-250830