- Architecture

- Industry

- Leisure

- uk >

- Industry >

- Inflatable plugs >

- Heat-resistant valves

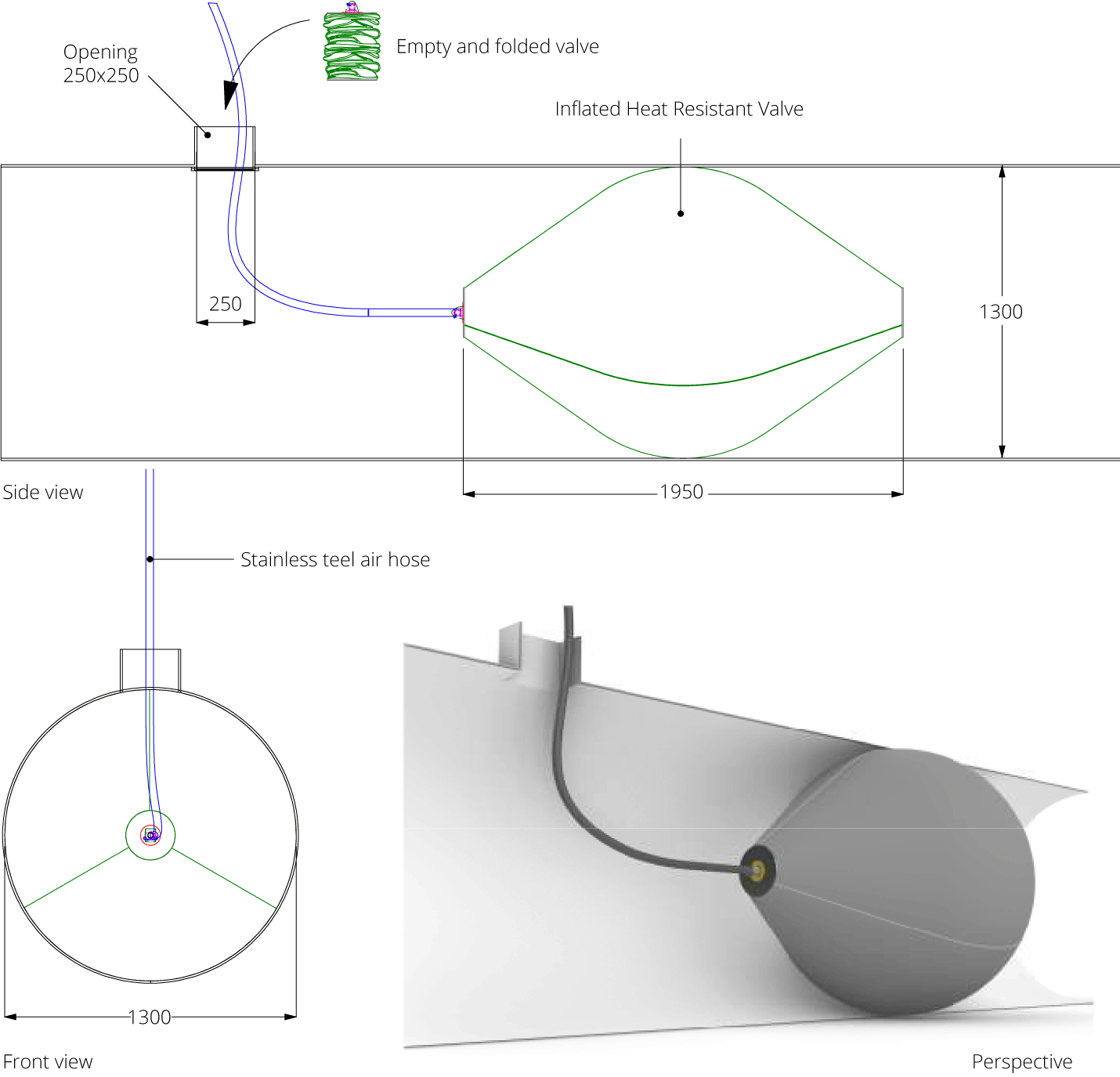

Heat-resistant inflatable valve

Up to more than 400 degrees Celsius!

Buitink Technology makes customized heat-resistant valves. We can make valves - to your specification - with a temperature resistance of more than 400 degrees Celsius!

Frequently, there are even more requirements than just high temperature resistance. Pipelines at high temperatures often contain other chemical substances and gases, such as sulphur dioxide (SO2) and sulphur trioxide (SO3). We also take this into account when selecting the materials from which to build the inflatable valve.

Applications heat-resistant valves

Heat-resistant valves can be used in many situations where alternatives are not (or no longer) possible or are much more expensive. Consider, for example, the following applications:

- Shutting off a pipe during inspection work;

- Shutting off a pipe during maintenance work;

- Shutting off a pipe during repair work or when replacing parts;

- Closing a chimney, during the shutdown of a production process, without excessive loss of pressure or temperature;

- Protecting against falling material during maintenance in pipelines.

Delivery includes pump and accessories

We do not only design, develop and produce the inflatable heat-resistant valve. We can also supply the necessary connections, (heat-resistant) hoses and air systems (with automatic pressure control), tailored to your project and your situation.

Example of pipe shut-off

On-site operational support

We supply complete, customized systems to protect pipes during projects or maintenance work, but can also provide on-site operational support if required:

- Installation supervision during installation of the inflatable valve;

- Assembly and installation of the inflatable valve;

- Disassembly and disposal of the inflatable valve;

- Operation of the air system;

- On-site monitoring;

- Remote monitoring (via data connection).

Materials

Depending on the specified requirements (e.g. temperature resistance and chemicals to which the inflatable valve will be exposed), we select the flexible materials from which the inflatable valve will be made.

A combination of different films, fabrics and coated cloths is often used to produce an inflatable valve that meets all requirements.

Below are some examples of the materials we use to assemble and manufacture inflatable heat-resistant valves:

- Fibre glass

- Ceramic fabrics

- PTFE film and foil

- PTFE-coated fibre glass fabric

- ETFE foil

- PFA foil

- FEP foil

- Silicone-coated fibre glass

- Aluminium foil

- TPU (thermoplastic polyurethane) foil

In-house testing

The inflatable valves, tailor-made by Buitink Technology, can be extensively tested, at your own premises or elsewhere. Consider, for example, the following:

- The temperature resistance of the inflatable valve;

- The chemical resistance of the materials used for the inflatable valve;

- The maximum air pressure that the inflatable valve can withstand;

- The flexibility and compactness of the inflatable valve in relation to its assembly/installation at the correct location in a pipe system;

- We can replicate (part of) the pipe system in our factory in Duiven, with lead-troughs, couplings and bends, to simulate and test the insertion and removal of the inflatable valve on a 1:1 scale to minimize the risks on site.

FAQ for customized, heat-resistant, inflatable valves

Is there a heat-resistant valve for every situation?

Of course, every situation is unique. However, precisely by identifying and mapping out the specific circumstances, environmental factors and requirements, together with the customer, we can almost always develop and produce a valve that meets the desired performance.

What preparations must be made to install a heat-resistant valve?

The great advantage of inflatable valves is that, until they are filled with air, they take up little space. This means that the space required to insert them - in a pipe system, for example - is also very limited. A round opening of only 25cm can be adequate to insert a valve with an inflated diameter of 150 cm into a pipe system.

Are heat-resistant valves also available for permanent use?

We recently developed a heat-resistant valve that was installed in a large pipe and is permanently incorporated in this pipe. As soon as major maintenance is required, this valve is pressurized; it closes the pipe (in this case a 300 cm diameter flue) and prevents pressure loss in the pipe system. This valve is directly connected to the local compressed air system.

How often can a heat-resistant valve be used?

Many versions can be used several times and are reusable. In very specific cases, the valve may only be used once. In most cases, the depreciation of the valve is disproportionate to the revenue and added value that its use offers, compared to alternative scenarios.

What sizes are available?

Over recent years, Buitink Technology has produced many different sizes and configurations of heat-resistant valves. Valves with diameters of a few centimeters to several meters. In some cases, even multi-chambered valves to achieve a good seal. In other words, we always find a suitable solution to your problem.

What are the maximum pipe pressures that heat-resistant valves can withstand?

That question is difficult to answer very precisely, because it depends very much on the specific situation in which the valve is located. Together with the customer, we look in detail at all parameters of the situation, such as pressure, dimensions, duration, temperature etc., and we work out a suitable solution on that basis.

How can we be sure that an appropriate solution is always provided?

If required, as part of our service, we can replicate the complete situation with piping and heat-resistant valve for you at our factory in Duiven. Process steps, such as the insertion, positioning, inflation and dismantling of the valve, can be simulated in this way so that the actual installation at the customer’s site, possibly under our supervision, proceeds smoothly and without surprises. This unburdens the customer and provides maximum assurance of a successful outcome.

What are the maximum temperatures for which heat-resistant valves are available?

There is a broad temperature window in which solutions are available. The maximum temperatures in combination with standing time that we have realized for customers to date is approximately 500 degrees Celsius over a period of 50 hours.

Questions?

Do you have questions or want more information? Please feel free to contact us. Call us at +31 (0)316-250830. But even easier: fill out the contact form below directly. We will contact you as soon as possible!

Contact form

Contact form +31 (0)316-250830

+31 (0)316-250830