- Architecture

- Industry

- Leisure

- uk >

- Industry >

- Lifting by Air >

- Marine airbags

Marine airbags

General

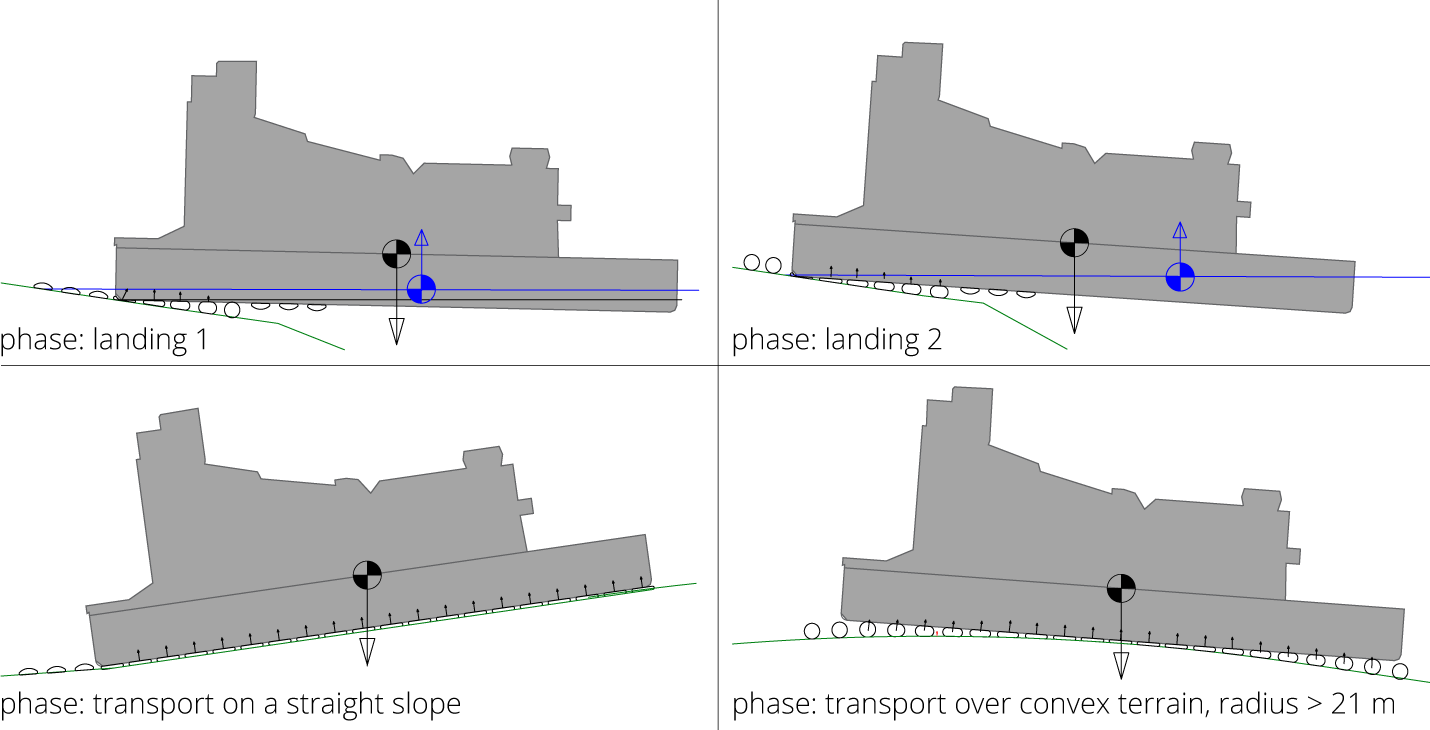

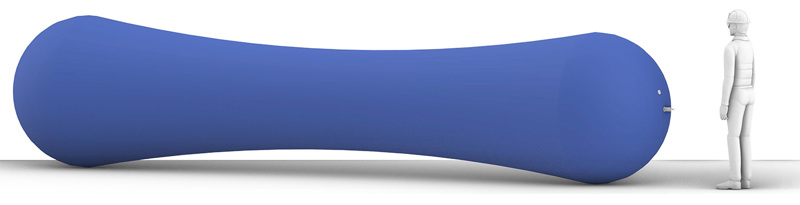

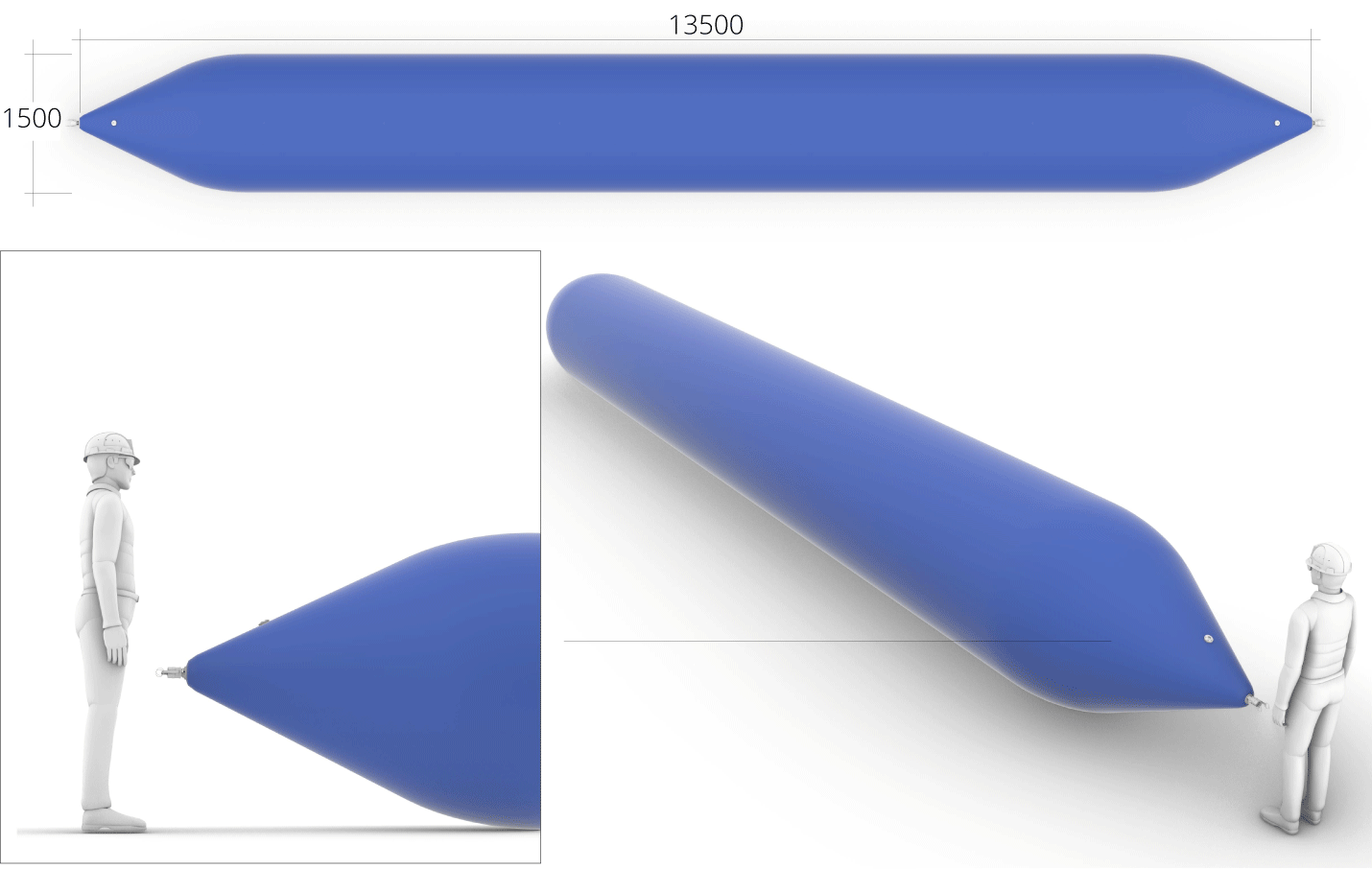

Buitink Technology develops and produces marine airbags which can be used as rollers on which to move large, heavy objects (e.g. when launching ships).

These airbags are made out of an extremely strong material: a TPU coated type of VII fabric with a break strength of 13,000 N/5 cm and a very high puncture resistance.

Check our website to see how we calculate the puncture resistance of a material:

For extreme situations, we reinforce the airbags with an extra layer of Aramid cloth. See our website for more information: about this super-strong material:

Made-to-measure in our own factory

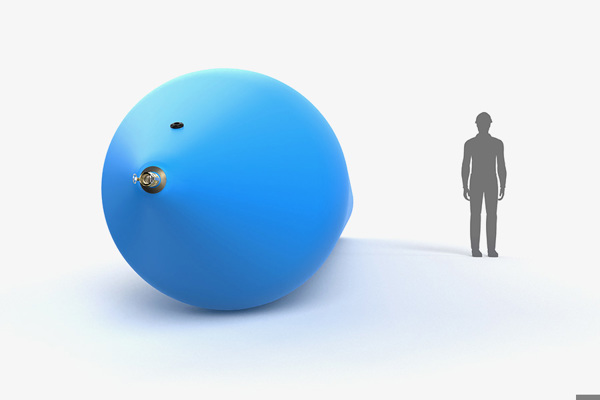

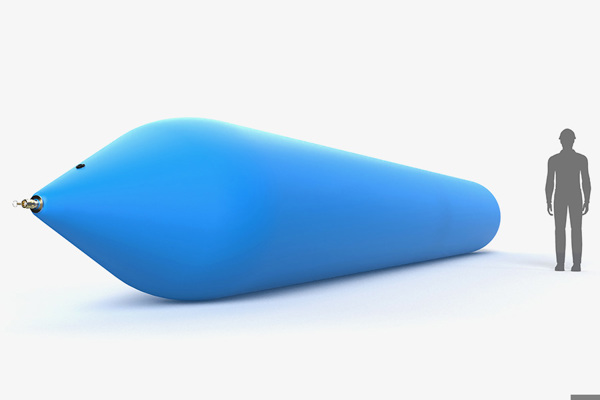

We manufacture custom marine airbags to measure at our factory in the Netherlands. Their diameters usually range from 50 to 250 cm.

Since we can supply custom work, we can also manufacture non-standard shapes, which means, for example, that we can produce tubes whose diameters increase towards the ends so that the object being rolled remains centered.

Transport and packaging

Buitink Technology’s marine airbags are characterized by their compactness when deflated and by their relatively very low weight. A Buitink Technology marine airbag generally weighs just 20% of the weight of a rubber alternative, i.e. five times lighter!

This allows us to ship our maritime airbags at attractive rates all over the world.

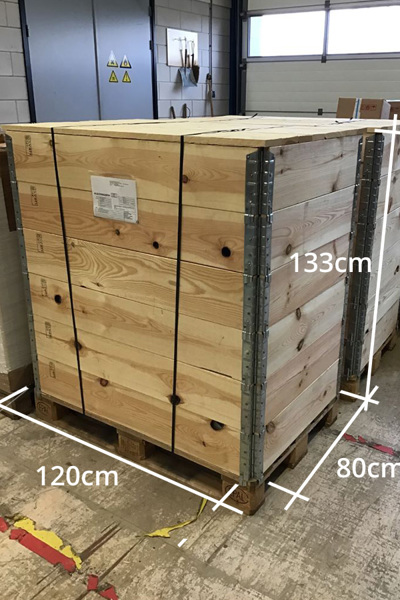

An example: 10 Heavy Duty, double layer marine airbags, each measuring 10 meters in length and 70 cm in diameter can easily be packed in two pallet boxes/boxes measuring 120 x 80 x 133 cm / 47 x 32 x 52 inches (l x b x h).

Together these 10 marine airbags weigh just 600 kg, i.e. 60 kg each.

Operational support

Not only do we supply the marine airbags, we can also supply the blower, air hoses and all the necessary couplings. You can also hire the blower and accessories from us. In addition, we can offer operational support. We can position and move the marine airbags and provide support during the operation where necessary.

The advantages at a glance

Compared to the alternative heavy rubber marine airbags, Buitink Technology’s airbags have a number of key benefits and properties:

- Relatively very low weight (only 20% or less of conventional rubber marine airbags);

- Very compact when folded;

- Quick and easy to position and reposition thanks to its low weight;

- Made-to-measure from our own factory;

- It is also possible to produce shapes other than straight tubes (e.g. tubes that taper towards the middle to center the weight);

- All sizes are possible and there’s a range of options with regard to thickness/height/inflated shape;

- Customized solutions can be delivered quickly;

- The material is flexible, making it relatively safe, preventing damage in the event of impact with the surroundings or other objects;

- This panel does not deform permanently under high forces or impact, but rather is flexible and simply bends with it (returns to its original shape);

- Resistant to all weather conditions, does not corrode;

- Ideal for use in maritime climate: excellent seawater and salt resistance.

Development and engineering of marine airbags

FAQ on inflatable marine airbags

When do you use Launching Tubes?

There are often situations in which heavy hydraulic lifting equipment, such as cranes, cannot easily be used due to a lack of space or the control needed to carry out the operation safely. In addition, being able to use the tubes repeatedly offers a significant cost advantage over what can often be high crane rental charges.

How do you calculate the size and number of Launching Tubes needed?

Obviously, that depends entirely on the scenario in which you intend to use the tubes. Our engineers use the information submitted on weight, dimensions, etc. to determine exactly which tube layout will be required for an operation to be completed successfully.

To what pressure are the Launching tubes inflated?

Launching Tubes are what are known as low-pressure airbags as they are inflated to no more than 0.5 bar. Built-in pressure relief valves ensure the release of pressure in case of overload whether during inflation or operation.

Can Launching Tubes be used more than once?

The material from which the tubes are made is extremely strong and is highly resistant to tearing and puncturing. Consequently, the tubes are very durable and can be put to use many times over. Should sharp parts cause any cracks or punctures, they can be easily fixed with the repair kit supplied. We can repair any severe damage at our factory in Duiven.

What kind of air pump is needed to inflate the Launching Tubes?

Filling the tubes with air requires a blower, preferably one on which the maximum air pressure can be set. Although there’s no need for the blower to build up high pressure in the tubes, it is handy if it is capable of pumping a reasonable volume so that the process does not take too long. You can rent a blower complete with filler hoses for use during your launch from Buitink Technology.

Do the Launching Tubes have to remain connected to the blower?

Once the tubes have been inflated and the filler coupling on the tube has been shut off, they can be disconnected from the air pump. If necessary, the launching tube can be topped up later on during the operation.

Can Buitink Technology supervise a Launching Tube operation?

Although our clients always bear responsibility for the operations, BT engineers can act as supervisors while operations are being carried out. During the launch, the supervisor will direct the operational crew on matters such as air pressure and where to position the tubes.

Do Launching Tubes come in standard sizes?

No, the size of the tubes is determined entirely by the shape and weight that is to be moved. On average their diameter ranges between 50 and 250 cm and the length from 5 to 10 metres. Every tube is therefore custom-manufactured at our factory in Duiven.

Buitink Technology Launching Tubes are lightweight. Doesn’t that mean they can be damaged very easily?

Clever use of materials does indeed make our tubes as much as five times lighter than rubber ones. However, despite their low weight, they are no less robust than heavier airbags and are perfectly capable of ensuring any launching operation is a success. They are resistant to saltwater and all types of weather conditions.

What is the best way of storing the Launching Tubes after use?

After use, the blower is used to suck the air out of the tubes making them very compact and easy to store. After cleaning, dry thoroughly and store in a well-ventilated area. To prevent ageing, store away from direct UV light.

Questions?

Do you have questions or want more information? Please feel free to contact us. Call us at +31 (0)316-250830. But even easier: fill out the contact form below directly. We will contact you as soon as possible!

Contact form

Contact form +31 (0)316-250830

+31 (0)316-250830