- Architecture

- Industry

- Leisure

- uk >

- Industry >

- Inflatable plugs >

- Inflatable cover

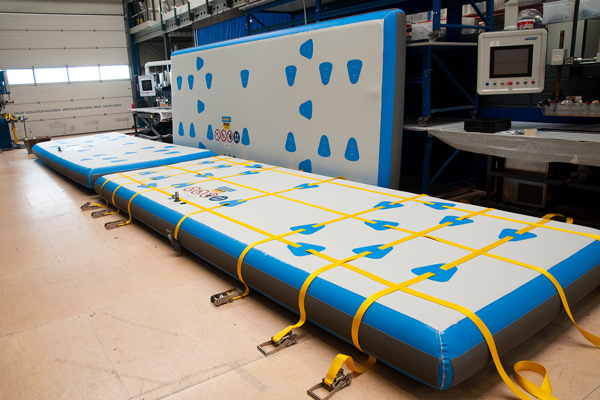

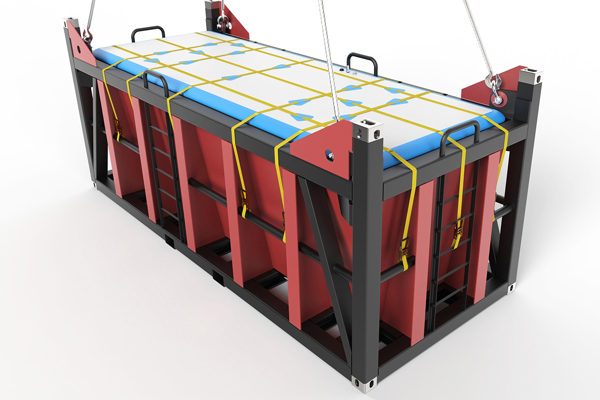

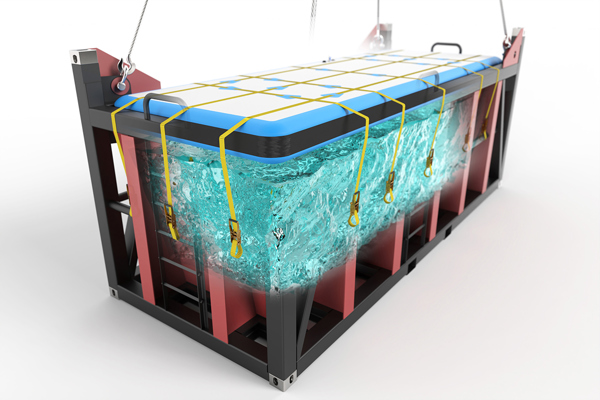

Inflatable cover

For sealing open containers

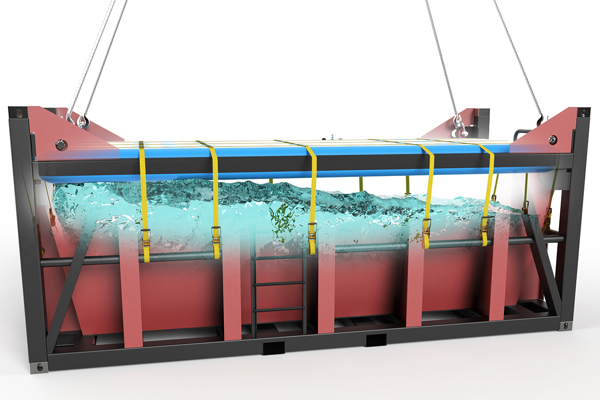

Buitink Technology makes inflatable covers to measure for containers, for example. When a container is filled with (bulk) goods, liquids or any other material that has to be stored or transported in a space that is closed from above, the top can be sealed with an inflatable cover from Buitink Technology.

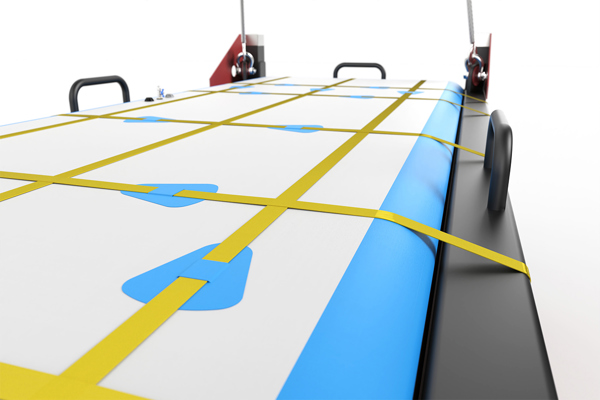

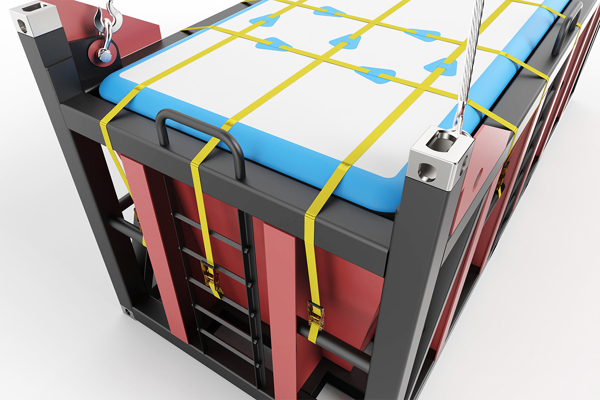

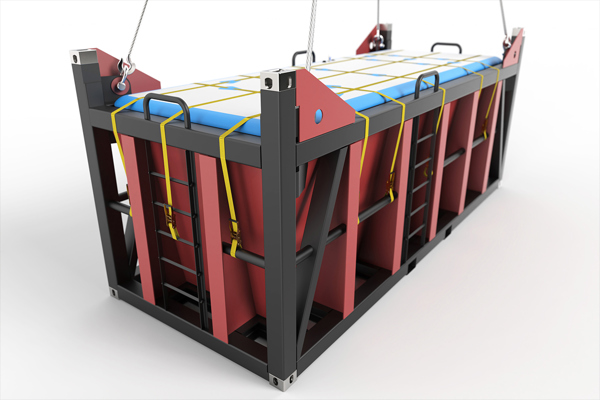

In many situations, a Buitink Technology inflatable cover is the ideal solution: it is lightweight and easy to handle, and the inflatable cover will not permanently deform permanently when a load is imposed; it always returns to the original shape. In addition, the inflatable cover seals the edges completely, as the lid is pressed against the container wall all around by air pressure. To enhance this, we also have special rubber seals that can be integrated into the inflatable edges of the inflatable cover.

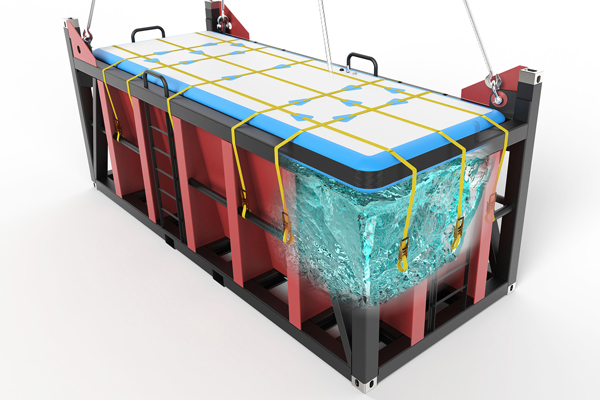

An example of the use of an inflatable cover is for sealing the tops of containers at sea, which are filled with, for example, polluted waste water that has to be transported to land. During storage and while being transported by sea, waste water must not flow or leak from the container, due to movements of the ship for example . It is difficult to fit a steel lid with a watertight edge seal, and this would also be heavy and difficult to handle. Also, a heavy steel lid can easily be damaged or deformed when opened or closed.

Made-to-measure from our own factory

The inflatable covers are fully developed, engineered, drawn and produced in-house. That means we can deliver quickly and implement the most suitable solution for your situation.

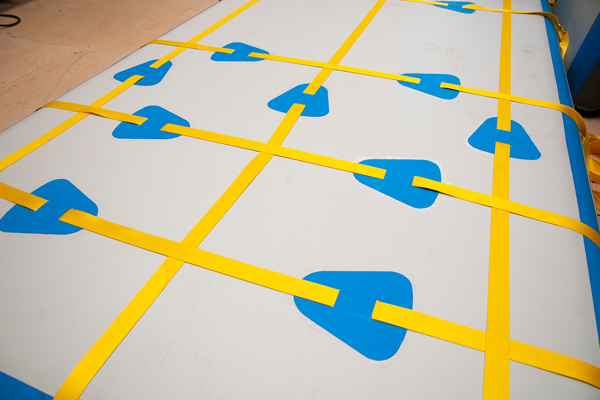

You can choose from many colors and different thicknesses/heights of the material when inflated. There are countless fastening options that we can apply (straps, loops, ropes, hooks, etc.). The lid can be made in various strengths and stiffnesses and it is also possible to produce the lid in, for example an anti-static or chemical-resistant material. Or we can use material with extremely high puncture resistance.

Do you have a specific application in mind for Buitink Technology’s inflatable cover? If so, contact us and describe your problem to us!

Transport and packaging

The inflatable cover is extremely lightweight: it generally weighs between 2.5 and 5.5 kg per m2, depending on the desired specifications and design. In its non-inflated state, the inflatable cover is very compact and takes up hardly any space when stored or transported to a site.

The advantages at a glance

Compared to the alternatives, the Buitink Technology inflatable cover has a number of important advantages:

- Made-to-measure from our own factory;

- All sizes possible, various choices of thickness/height in inflated condition;

- Customized solutions can be delivered quickly;

- Extremely light in weight;

- Very compact when folded;

- The inflatable cover can be installed at any level in the container, or even float or lie on the liquid or material in the container, after which the lid can be inflated and clamped in place (and further secured with straps). Large movements of the liquid are thus prevented.

- The material is soft and flexible, making it relatively safe and thereby preventing impact damage with its surroundings or other objects;

- It does not deform permanently under high forces or impact, but is flexible and simply bends with them (then returns to its original shape);

- Resistant to all weather conditions, does not corrode;

- Very good all-round closure due to the inflatable edges which press and hold tight against the side walls;

- Quick and easy to assemble and disassemble;

- Ideal for use at sea: very good seawater and salt resistance, easy and safe to handle and easily absorbs very large shock forces (due to wind or when ship is in a storm with high waves);

- Can also be used as a "traditional" tarpaulin when not inflated.

Engineering of the inflatable cover

Inflatable Cover FAQ

What information is required to order an inflatable cover?

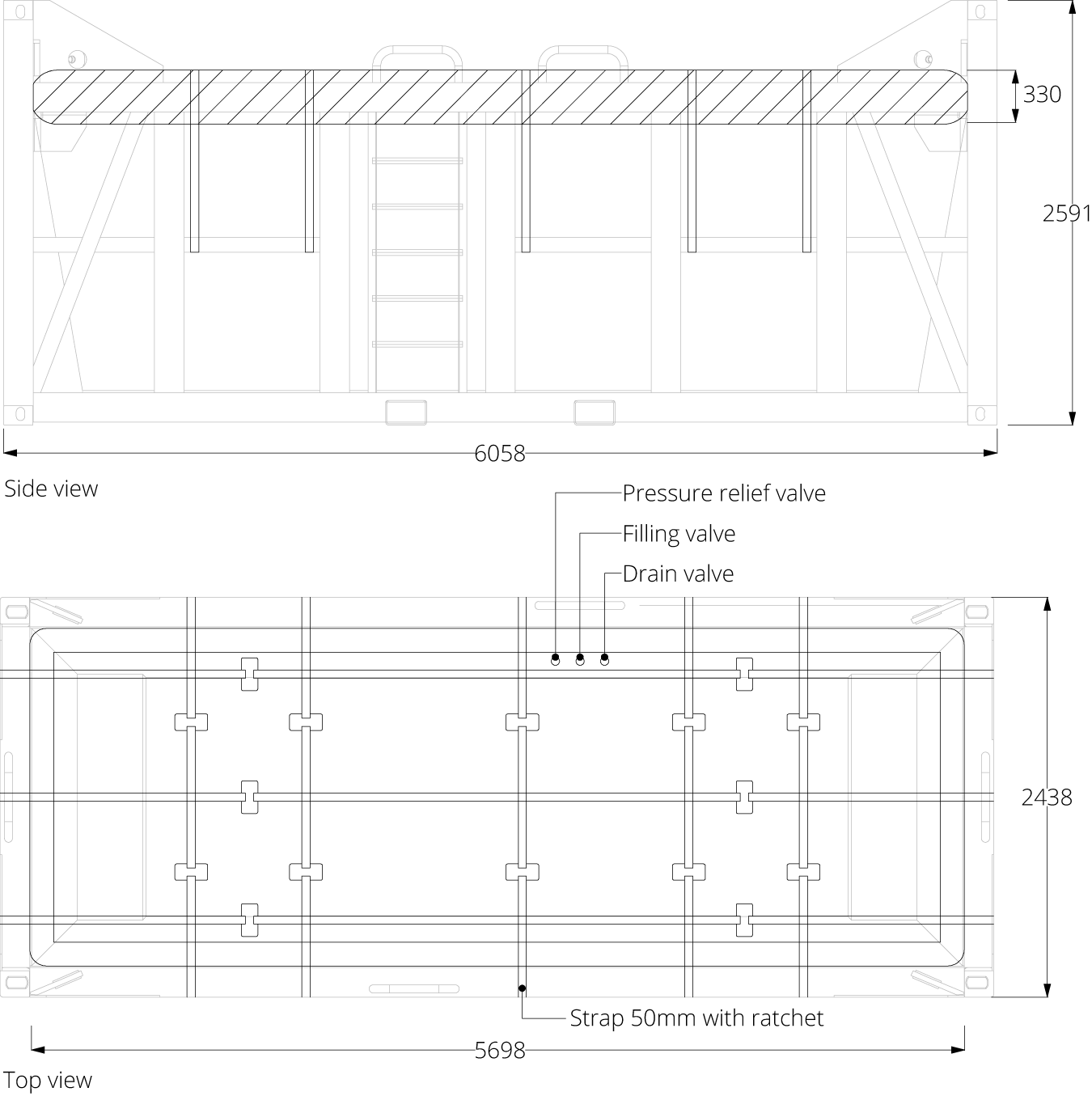

That depends on what you intend to use the cover for. We know the dimensions for closing the top of a standard 20 or 40 ft container. In all other cases, please provide us with the interior dimensions of the container or bin you wish to seal. We will then produce a customised cover for you

Is an inflatable cover always rectangular or square?

In addition to these shapes, we can also produce the cover in other shapes, such as round or triangular. Combinations of these forms are also possible. Based on a drawing or sketch, supplemented with measurements, we can prepare a quotation for you.

How do I fill the cover with air, and with what?

The cover is equipped as standard with filling valves, to which you can connect an air hose. Depending on the type of pump or compressor you work with, and the diameter of the air hoses, we can also adapt these filling valves for you if required. The pump capacity determines the speed at which you fill the cover.

Do I need a special pump or compressor?

The cover is a so-called low-pressure cushion. In practice, this means working with pressures that do not exceed 1 bar. You therefore do not need special air systems or pumps to tension the cover. In fact, you can even fill the cover perfectly with a decent hand pump. Of course, if fast operational readiness is desired, an electric pump will be more suitable.

Does the cover always have the same thickness?

As standard, the cover is designed to be approximately 30 cm thick, but there are options for deviating from this. Tell us your wishes, and together we will see which size serves your situation best. There are several thicknesses available in addition to the standard size.

In the event of damage, can I repair the cover myself?

The clamping lid is in itself very robust and will therefore not easily show damage or wear. Should any damage occur, it is easy to repair it yourself using the repair kits that we can supply. You do not have to write off the cover even in the event of serious damage; we repair all damage in our factory and return the clamp cover as new.

Is the cover resistant to aggressive chemicals?

The materials from which the cover is made are highly resistant to many types of liquid. In the case of specific aggressive chemicals, we can design/coat the cover with materials that have very high resistance to these types of liquid. Let us know exactly what you are looking for and we will sort it out for you.

Where do I put a terminal cover that is not in use?

As soon as you deflate the cover or suck the air out of it, all that remains is a small package that you can easily store. To enhance the life of the cover, it is important to store it dry in a well ventilated space and away from direct sunlight.

I want to print the cover with our company logo; is that possible?

We can print the top and/or bottom with your company logo or other forms of advertising or communication in full colour. If you provide us with the desired print in the correct digital format, we will take care of the rest.

Questions?

Do you have questions or want more information? Please feel free to contact us. Call us at +31 (0)316-250830. But even easier: fill out the contact form below directly. We will contact you as soon as possible!

Contact form

Contact form +31 (0)316-250830

+31 (0)316-250830